東英グループからのお知らせ

- 2024.4.8

- お知らせ

- 福島県会津での「かんます1周年記念イベント」に参加させて頂きました。(IoT日本酒サーバー「のまっせ」登場) 記事を見る>

- 2024.2.26

- イベントお知らせ

- 「Deep Tech Forum Kyoto」(2024年3月7日~8日、於京都)に参加致します。 記事を見る>

- 2024.1.22

- お知らせ

- 東莞東英電子工業の忘年会が行われました。 記事を見る>

ブログ

- 2024.4.17

- 製造

- 電化製品におけるOEMとは ~メリット・デメリットを徹底解説~ 記事を見る>

- 2024.3.22

- イベント

- 「Deep Tech Forum Kyoto 2024」に参加しました 記事を見る>

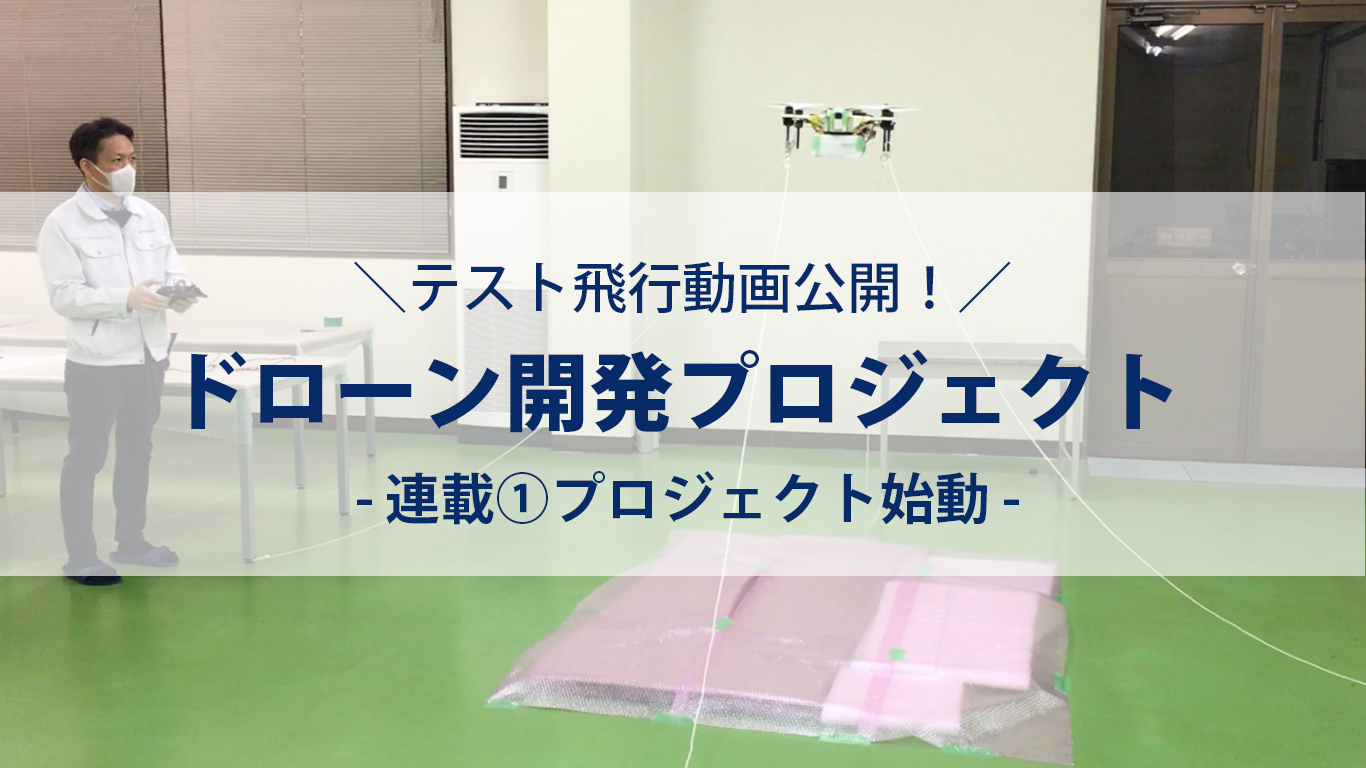

- 2024.2.29

- ブログ

- 【テスト飛行動画公開!】ドローン開発プロジェクト -連載①プロジェクト始動- 記事を見る>

- 2024.2.21

- イベント

- 東莞東英電子工業の忘年会が行われました 記事を見る>

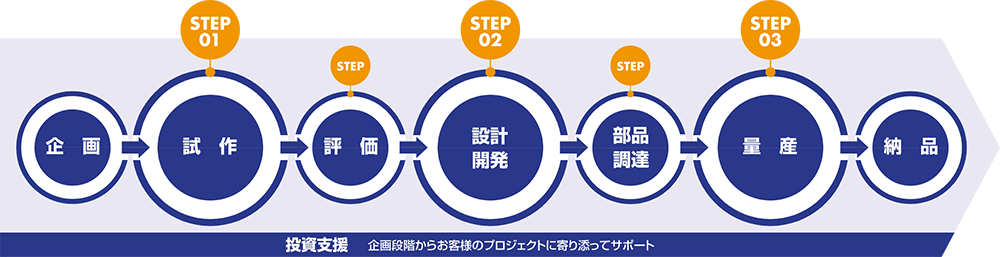

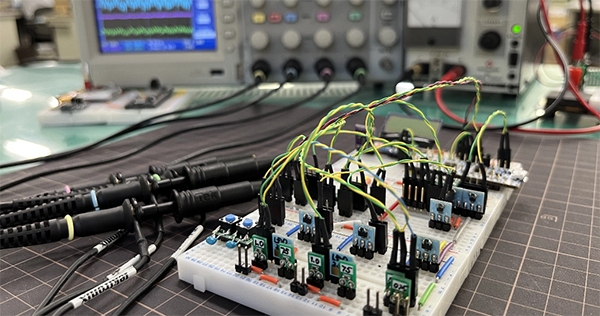

試作(プロトタイピング)

開発の企画設計から「試作」段階に於いて、その後の「開発」「量産」「納品」までの 全体を見据えてマネジメントしていきます。モノづくりのプロとして、開発規模や予算、品質などのご要望に合わせた最適解をご提案します。

試作事業をもっと知る>

量産

安心の「国内生産」、価格競争力が生きる 「海外生産」、その組み合わせである 「国内最終生産」、お客様の要望に合わせた プランをご提案します。 最適な生産拠点と必要な設備の活用で、小ロットから大量生産まで幅広く対応が可能です。

量産事業をもっと知る>

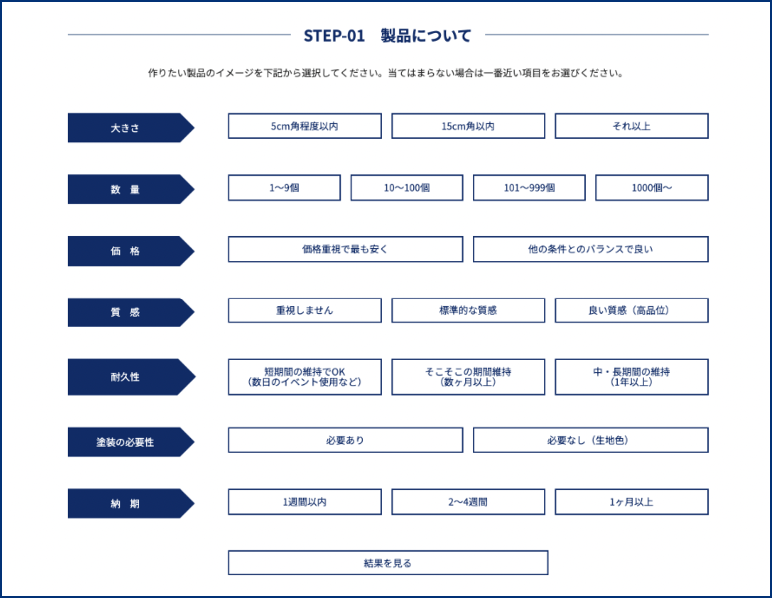

樹脂部品相談システム

数字で見る東英グループ

- 創業年

- 1971年

- 設計実績

(直近10年) - 約1200件

- 製造実績

(直近10年) - 約5000件

- 海外での部材調達額

(直近10年) - 485億円

- 累計投資額

- 3億4000万円

※上記は2022年4月時点の数値となっています。