Language Switching

Language Switching

HOME > Business Areas > Design and Development

Tohei Group considers design and development as a part of manufacturing, and our strength lies in our ability to make efficient one-stop proposals assuming the flow to mass production.

We can also provide added value in total.

Our experienced development team of design professionals is responsible for your project. Under confirming customers' requirements we make proposal-based designs that are best suited. We will make flexible proposals that meet not only the quality and safety requirements, but also the needs of product specifications, budget and schedule.

We support the promotion of manufacturing by providing a wide range of expected services from designing next-generation products, prototyping and the handling of mass production to providing technology to universities and other R&D institutions, as well as start-up companies.

01

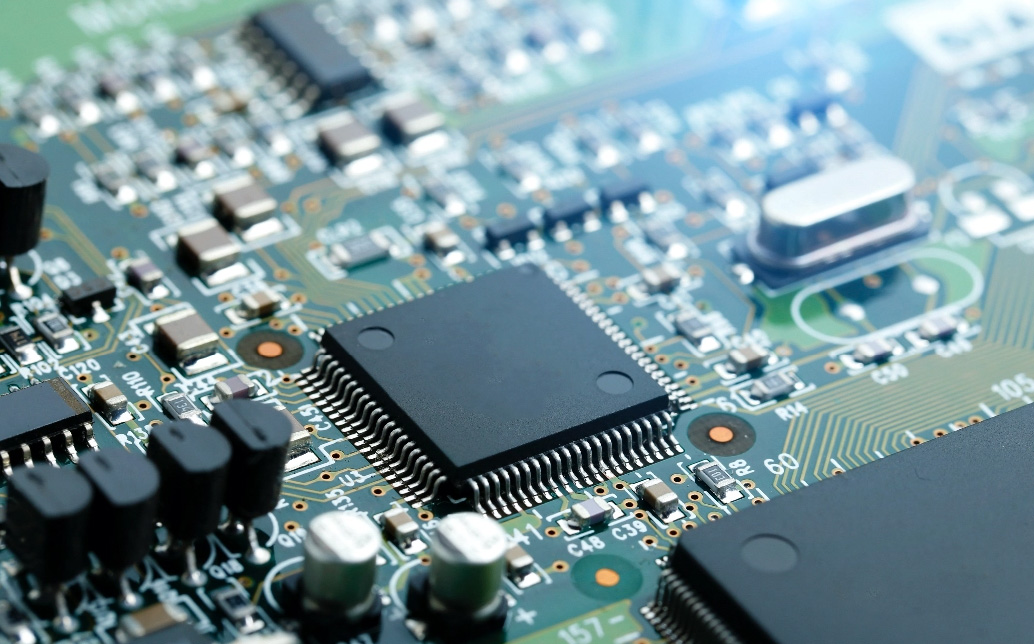

High functionality, high precision and miniaturization realized by our development capabilities

02

You can rest assured to entrust us with finished products business from prototyping to productization

(ODM/OEM/EMS)

03

Providing technology to achieve new businesses and to realize creative ideas

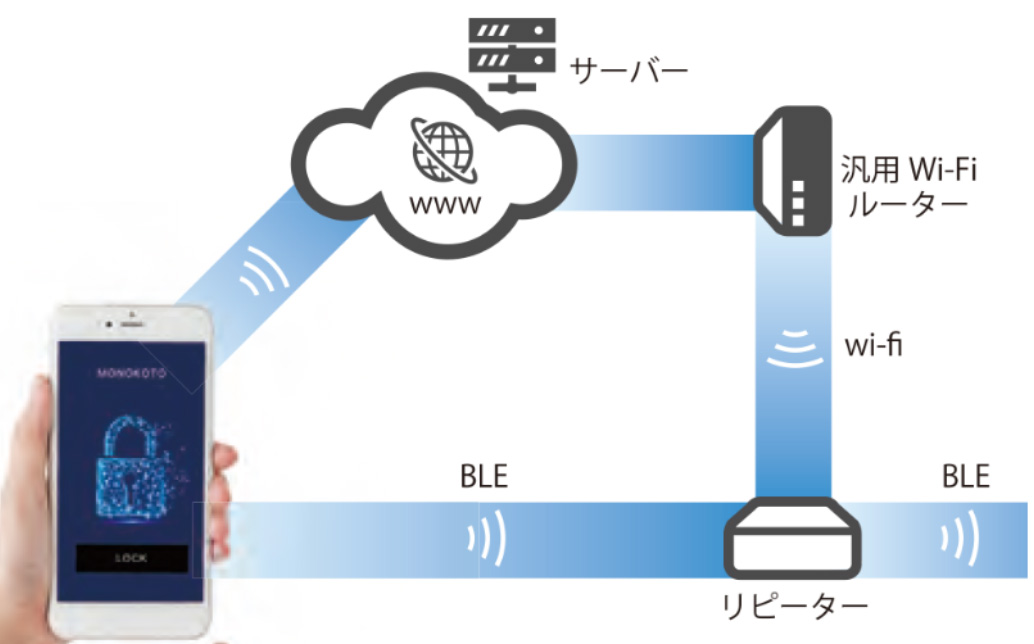

<Reference image: Key system that enables locking and unlocking of locks by a smartphone application>

04

Collaboration for next-generation technologies and the productization of R&D results

Process is important in proceeding the development. We will follow up firmly at each stage and proceed while confirming the progress.

![]()

STEP01

Contact us

Please feel free to consult with us about specific plans such as new design, improvement of existing products or realization of creative products, even when you are at the draft stage.

![]()

STEP02

Specification meeting

We will confirm the request of customers and discuss from various perspectives, such as product use environment and its usage, operation and control specifications, size, weight, certification acquisition and cost, etc.

![]()

STEP03

Proposal of Design and Specifications

We will integrate new technologies and usability into the proposal based on the customer's requirements. We work together with our customers to create development concepts and specifications.

![]()

STEP04

Prototyping Design

We give shape to the concept. We produce the prototype rapidly by identifying and improving various problems. We will establish core technology through evaluation and improvement design.

![]()

STEP05

Function, Performance and Design

We complete the final product, perform evaluation and verification based on a design that meets the requirements of final shape, function and performance. We select parts with the consideration of mass production.

![]()

STEP06

Mass production Design

Our design takes into account the conditions of the mass production plant, assembly, mounting, molding, etc. We select readily available parts, and responsible for the packaging design and shipping test design.

![]()

STEP07

Reliability, Evaluation and Certification

Various tests are performed by in-house and external testing equipment. For mass-produced products, we will assist in obtaining certification upon request. We provide support in obtaining third-party certifications

![]()

STEP08

Delivery of products

We will ship prototypes and functional products directly to the customer, and mass-produced products will be shipped directly to the warehouse specified by the customer. With our support, mass production is carried out in both domestic and overseas plants.